- 15-05-2024

- Joris Bracke

- 0 Comments

The “new” Part L1 of the Building Regulations came into force in June 2022, with a raft of improvements to meet the UK Government’s net zero carbon ambitions.

What are the changes?

Amongst the revisions is a reduction to the maximum flow temperatures of newly installed and fully replaced wet heating systems, which is now 55?C.

There was a 12 month “grace” period for projects which were approved under the previous Part L1 Documents (Part L1a and L1b 2013 as amended), provided building works were commenced before 15th June 2023. As this window has now closed, all new projects which did not start, and all new developments whether it be new builds, conversions, extensions or renovations must now fully comply with the latest Regulations.

Paragraph 5.10 of Part L1 2021 states;

“Where a wet heating system is either:

a. Newly installed

b. Fully replaced in an existing building, including the heating appliance, emitters and associated pipework

all parts of the system including pipework and emitters should be sized to allow the space heating to operate effectively and in a manner that meets the heating needs of the dwelling, and a maximum flow temperature of 55C or lower.”

Interestingly the hot water provision is ignored in this section, however there is a requirement to comply with BS EN 12831-3. We will cover this topic in a separate blog.

The Regulation goes on to state if its not feasible to install a space heating system that is able to operate at this temperature, for example, if there is insufficient space for larger radiators, then the heating system shall be designed to the lowest possible flow temperature to meet the space heating needs.

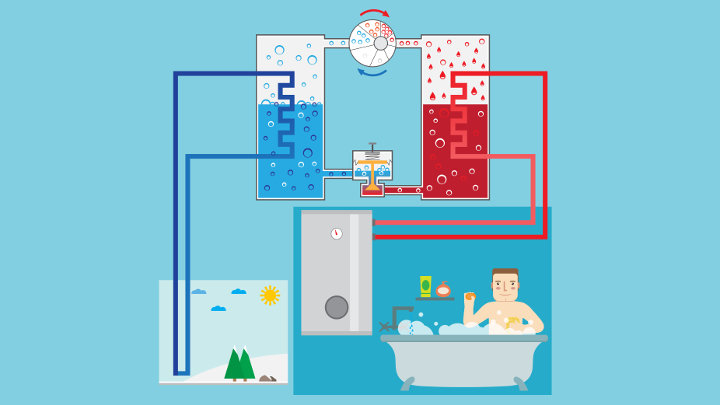

In addition, Part L1 2021 recommends that new dwellings fitted with an air source heat pump have a maximum flow temperature of 45?C.

Why have these changes been made?

The reasoning behind this change is to “future proof” properties initially fitted with traditional fossil fuel boilers, so that they can be easily and more cost effectively be retrofitted for low temperature heating systems (such as Heat Pumps).

The UK Government have laid out their ambitions to reduce carbon emissions from dwellings in the “New Homes Standard” which is due to come into effect in 2025.

How does this affect me?

Depending upon the installation, it may be possible to calculate the heat demand of an existing dwelling to a temperature higher than 55°C flow temperature, for example where an older gas boiler is being replaced with a modern condensing type and the radiators are not being upgraded.

However, if a heating system is being installed in a “newly created dwelling”, whether that be a new build or change of use / conversion, or if a dwelling is being renovated and all the flow and return pipework is being replaced along with the radiators and heat generator, then the maximum 55°C flow temperature will need to be complied with.

What do I need to do?

The correct sizing of heating systems with low flow temperatures is now more crucial than ever before as it is a Building Regulations requirement.

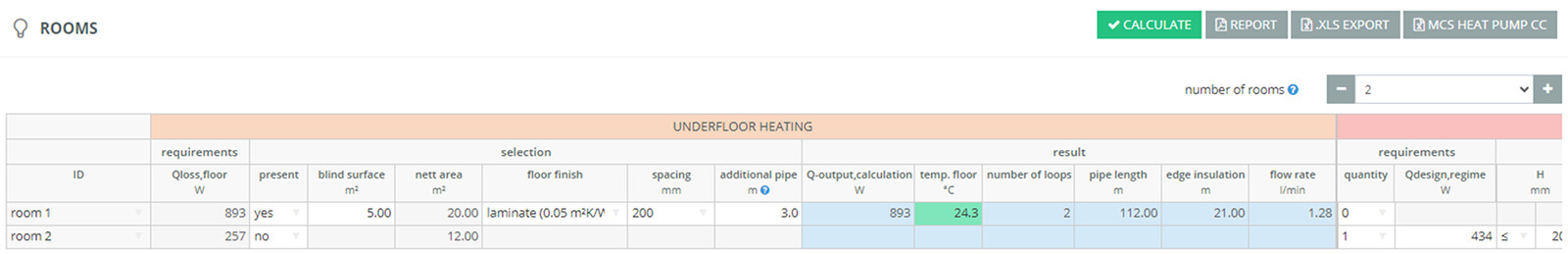

Heat-Box assists designers and installers in the correct sizing of emitters, whether it is underfloor heating or radiators. Our Heat-Box software also calculates the power requirement for each room in accordance with BS EN 12831, which is Micro Generation Certification Scheme (MCS) compliant.

Heat-Box has an integrated database which includes radiators from more than 15 manufacturers, and multiple product ranges. It is also possible to select radiator types (11, 21, 22 & 33) and the software automatically calculates the radiator which meets the minimum heat demand for each room.

The drop down box (as shown below) allows you to pick a radiator’s physical width and height to meet your specific requirements for that room.

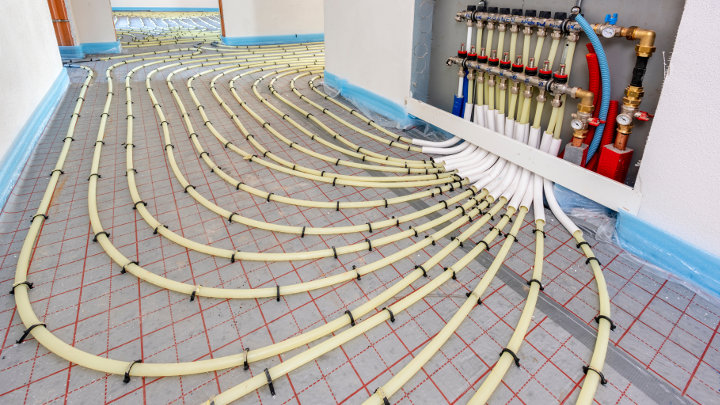

For underfloor heating, Heat Box offers the input of various floor finish types (i.e. carpet, stone tiles, laminate) to further refine the heat output requirements, along with calculating total heating pipe lengths, number of loops and also the flow rate in litres per minute. This saves time in calculating quantities, and manifold flow rates.

For further information regarding the Heat-Box suite of software, please visit heat-box.co.uk to request a free trial, and also our contact details to discuss how we can work with you to meet compliance with the new Regulations.

Comments

No comments yet.

Make a comment